Difference: GMT_cranioplasty (1 vs. 3)

Revision 3

15 Jul 2014 - gmt11

| Line: 1 to 1 | ||||||||

|---|---|---|---|---|---|---|---|---|

Dr Graham Treece, Department of Engineering | ||||||||

| Line: 20 to 20 | ||||||||

|

| ||||||||

| Changed: | ||||||||

| < < | ||||||||

| > > | ||||||||

| Changed: | ||||||||

| < < | ||||||||

| > > | ||||||||

| Line: 33 to 33 | ||||||||

|

| ||||||||

| Changed: | ||||||||

| < < | ||||||||

| > > | ||||||||

| Changed: | ||||||||

| < < |

| |||||||

| > > |

| |||||||

| Line: 48 to 48 | ||||||||

|

| ||||||||

| Changed: | ||||||||

| < < |

| |||||||

| > > |

| |||||||

| Changed: | ||||||||

| < < |

| |||||||

| > > |

| |||||||

| Line: 64 to 64 | ||||||||

|

| ||||||||

| Changed: | ||||||||

| < < |

| |||||||

| > > |

| |||||||

| Changed: | ||||||||

| < < | ||||||||

| > > | ||||||||

| Line: 76 to 76 | ||||||||

|

| ||||||||

| Changed: | ||||||||

| < < | ||||||||

| > > | ||||||||

| Changed: | ||||||||

| < < |

| |||||||

| > > |

| |||||||

| Line: 89 to 89 | ||||||||

|

| ||||||||

| Changed: | ||||||||

| < < |

| |||||||

| > > |

| |||||||

| Changed: | ||||||||

| < < | ||||||||

| > > | ||||||||

| Line: 102 to 102 | ||||||||

|

| ||||||||

| Changed: | ||||||||

| < < | ||||||||

| > > | ||||||||

| Changed: | ||||||||

| < < |

| |||||||

| > > |

| |||||||

| Line: 115 to 115 | ||||||||

|

| ||||||||

| Changed: | ||||||||

| < < |

| |||||||

| > > |

| |||||||

| Changed: | ||||||||

| < < | ||||||||

| > > | ||||||||

Revision 2

15 Jul 2014 - gmt11

| Line: 1 to 1 | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dr Graham Treece, Department of Engineering | |||||||||||||||||||

| Line: 6 to 6 | |||||||||||||||||||

ENGINEERING TRIPOS PART IIA

Module 3G4 - Medical Imaging and 3D Computer Graphics | |||||||||||||||||||

| Changed: | |||||||||||||||||||

| < < |

HTML, Java and GLUT demos | ||||||||||||||||||

| > > |

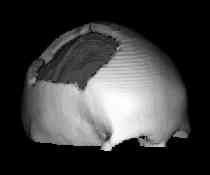

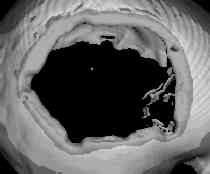

Titanium cranioplasty | ||||||||||||||||||

| Added: | |||||||||||||||||||

| > > |

In this work, medical imaging, computer graphics, surface interpolation and computer-controlled milling are used to create titanium cranial implants at Christchurch Hospital, New Zealand. Researchers: Jonathan Carr, Richard Fright and Rick Beatson, now with Applied Research Associates NZ Ltd .

Author: Jonathan Carr. | ||||||||||||||||||