Main > GMT_cranioplasty

Dr Graham Treece, Department of Engineering

ENGINEERING TRIPOS PART IIA

Module 3G4 - Medical Imaging and 3D Computer Graphics

Titanium cranioplasty

In this work, medical imaging, computer graphics, surface interpolation and computer-controlled milling are used to create titanium cranial implants at Christchurch Hospital, New Zealand.

Researchers: Jonathan Carr, Richard Fright and Rick Beatson, now with Applied Research Associates NZ Ltd .

|

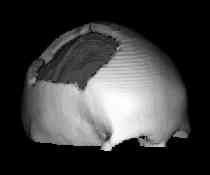

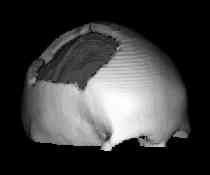

Ray-tracing is used to depict bone surfaces within a stack of CT data slices.

|

|

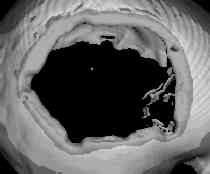

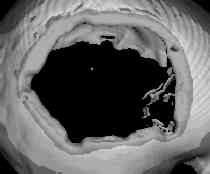

user graphically identifies a defect in the skull by highlighting the sound bone surrounding the defect

|

|

|

|

|

Radial basis function (RBF) approximation is used to fit a surface to the incomplete depth-map corresponding to the rendered view of the defect. The surface of the skull is smoothly interpolated across the defect. The thin-plate spline basis is chosen in this application.

|

|

A computer numerical controlled (CNC) mill produces a model of the defect and a mold in the shape of the interpolated surface.

|

|

Flat titanium plate is pressed into the mold in a hydraulic press.

|

|

|

The finished annodised plate fits the mold.

|

|

The perimeter holes in the plate are for the mounting screws and the central holes allow fluid to circulate. Perforations give the plate a limited amount of adjustment in theatre.

|

|

|

The plate is fixed in place with titanium screws.

|

Author: Jonathan Carr.