Main > GMT_4YP_24_2

Dr Graham Treece, Department of Engineering

F-GMT11-2: Prediction of metal artefacts in CT data

|  |  |

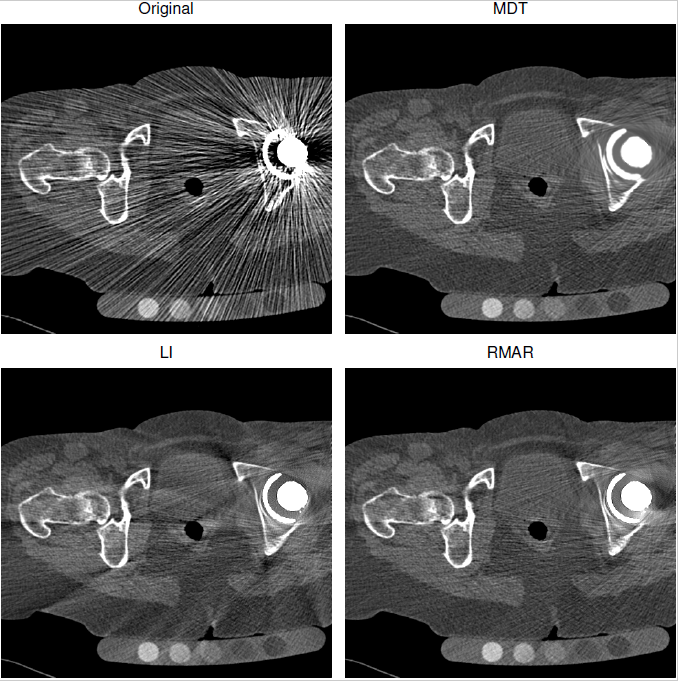

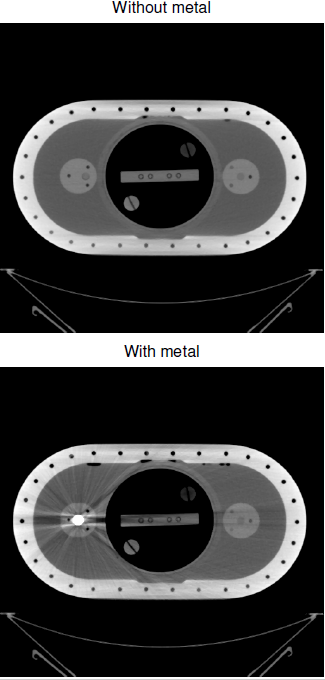

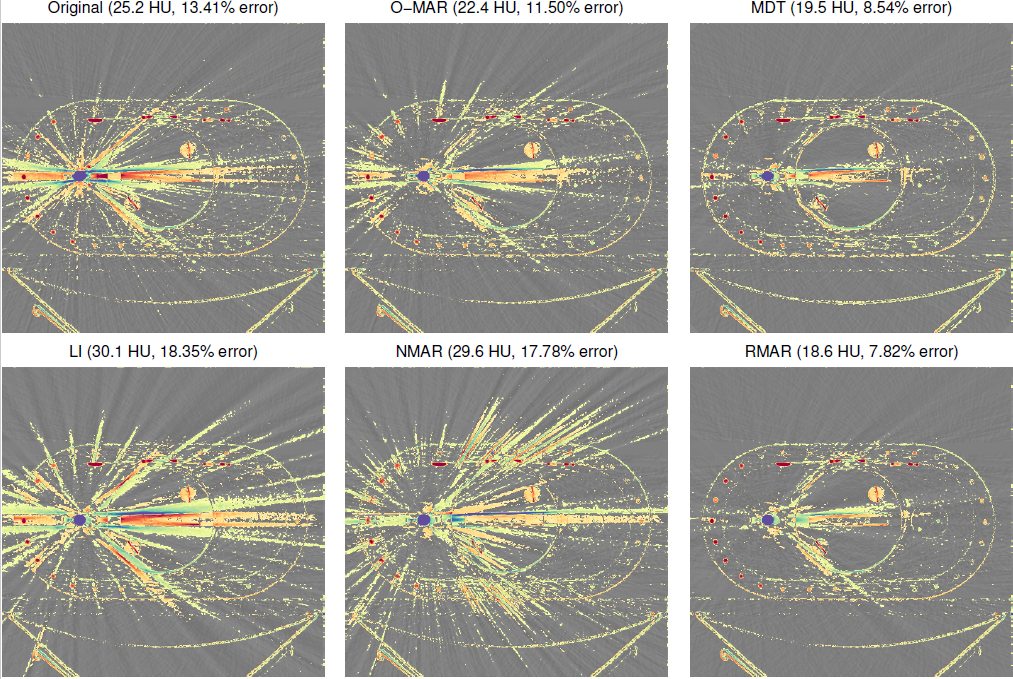

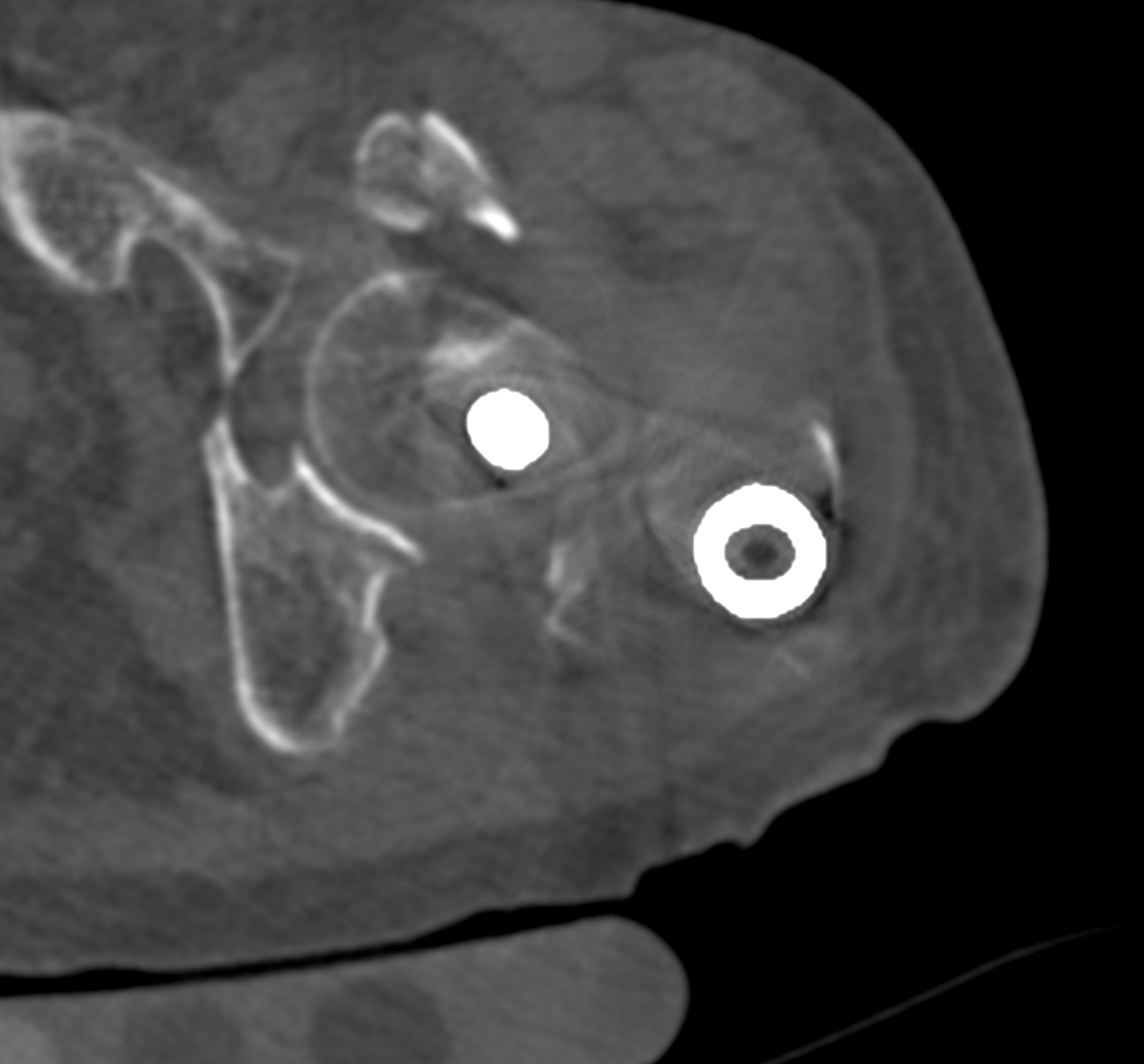

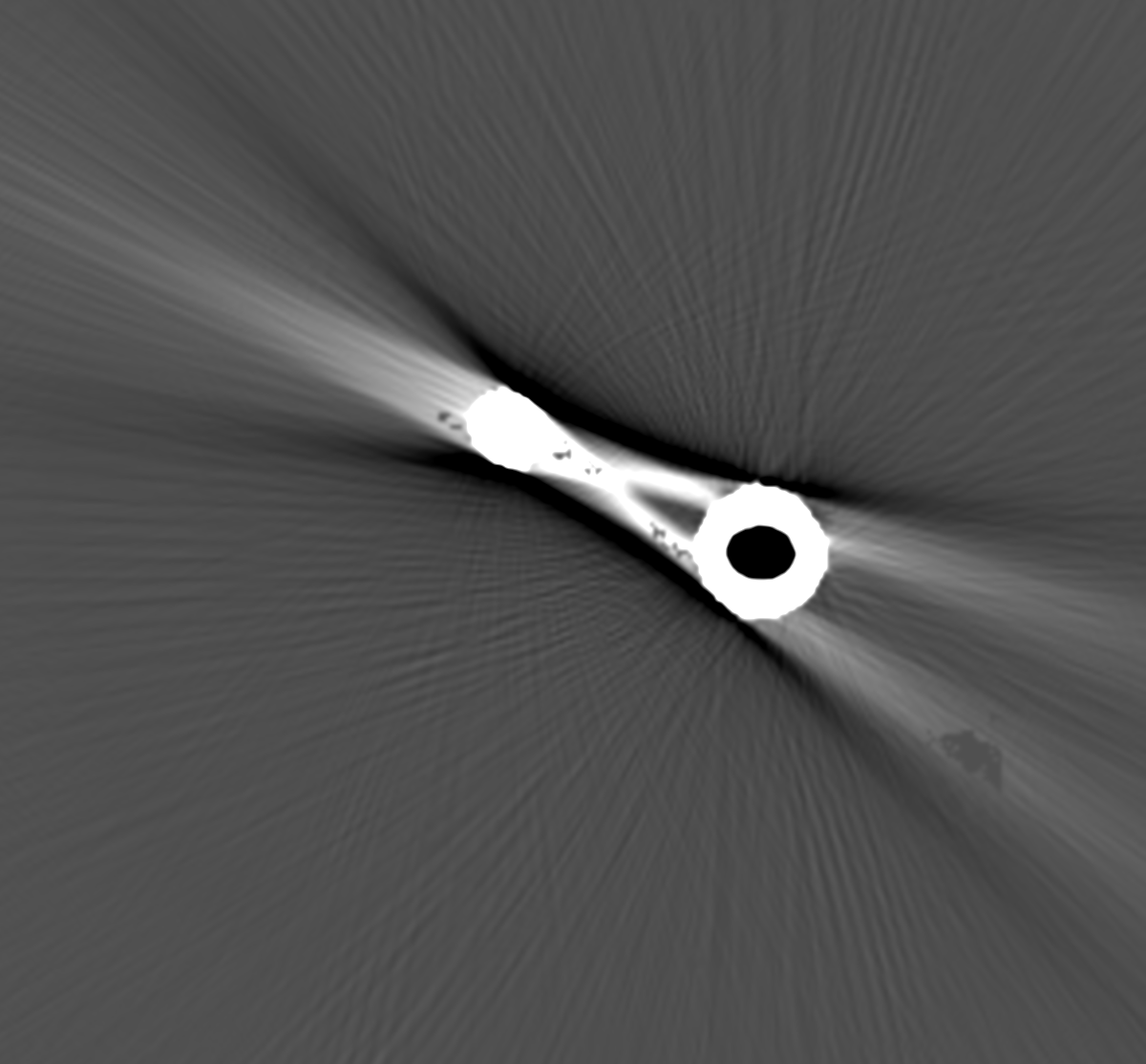

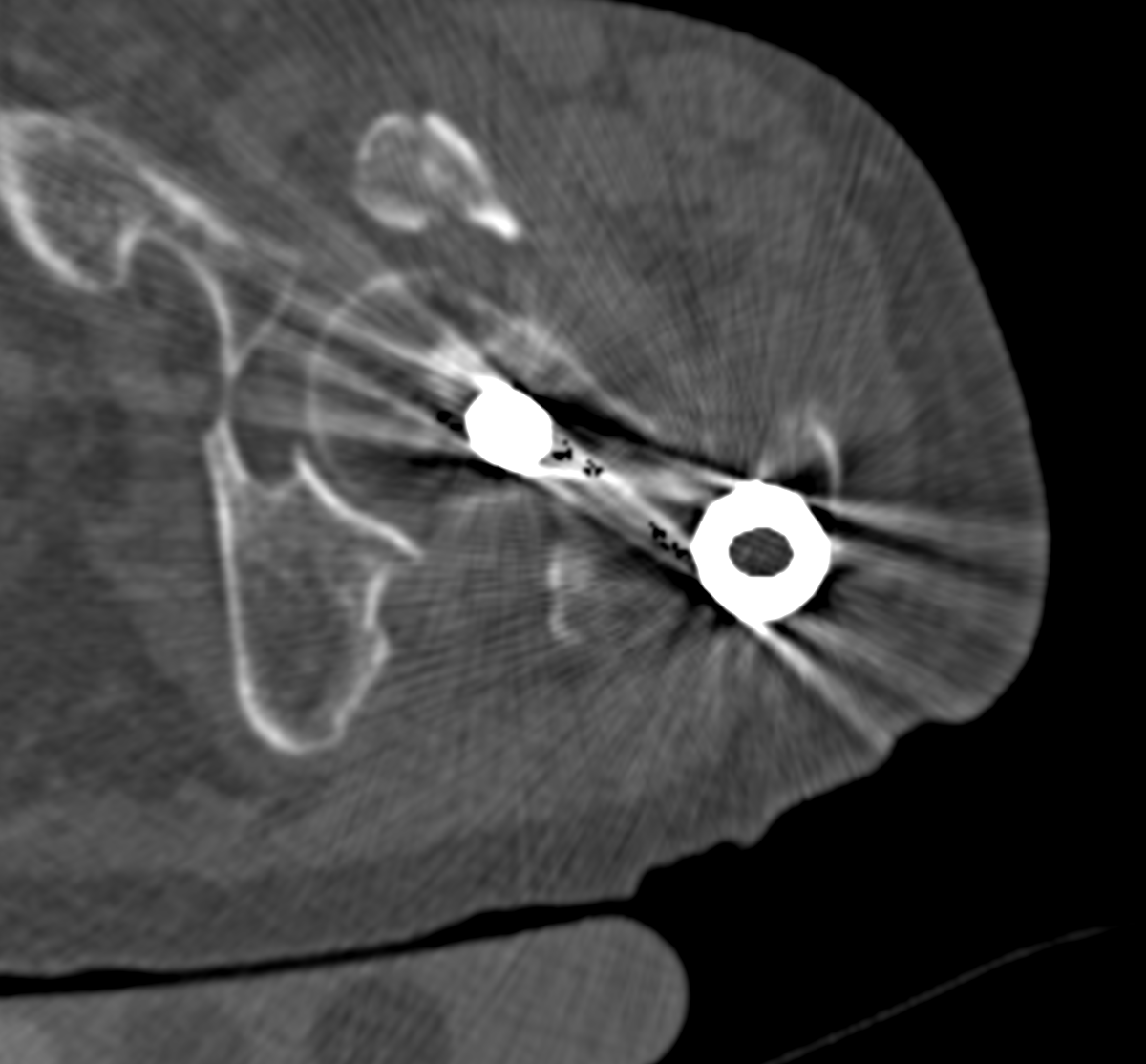

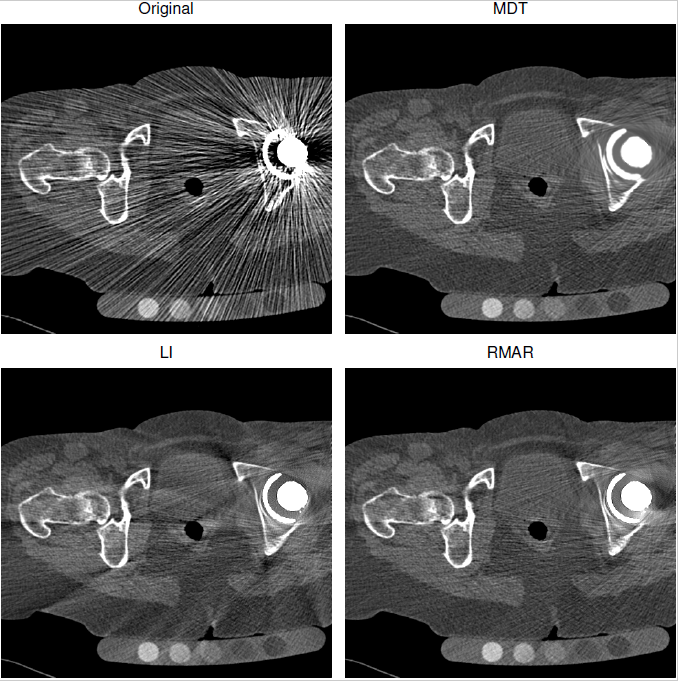

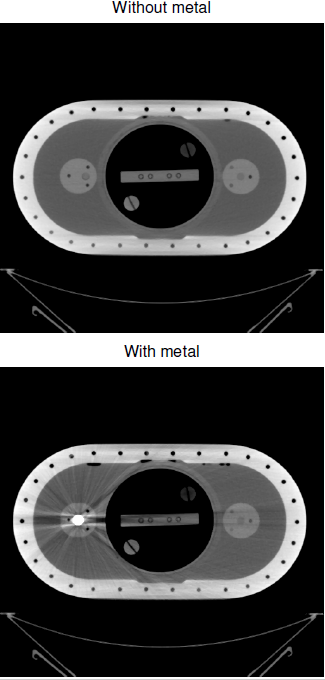

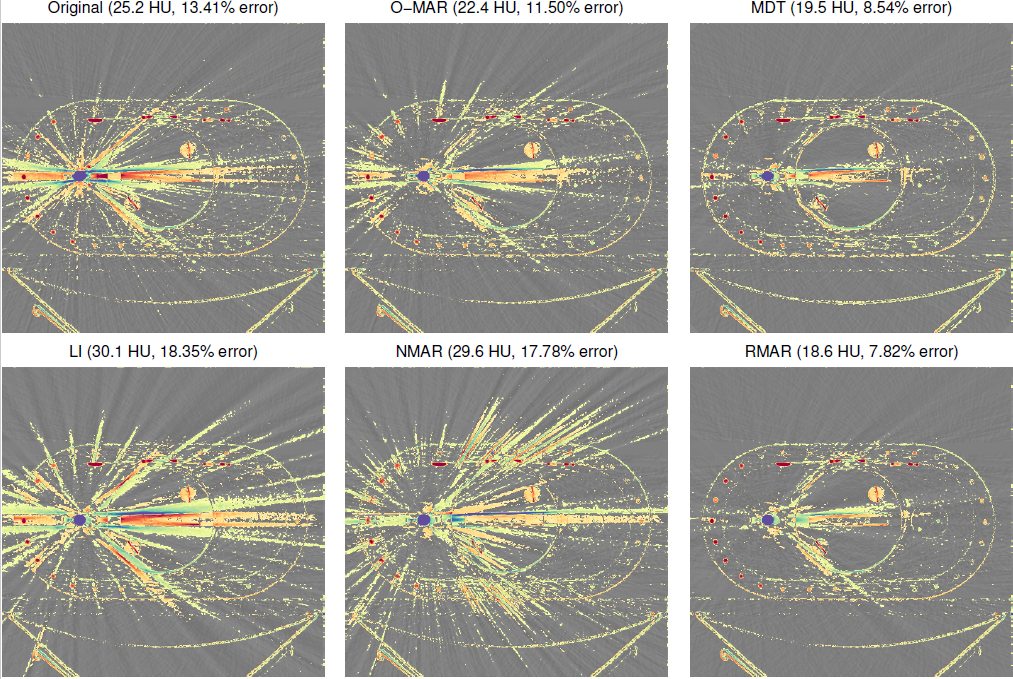

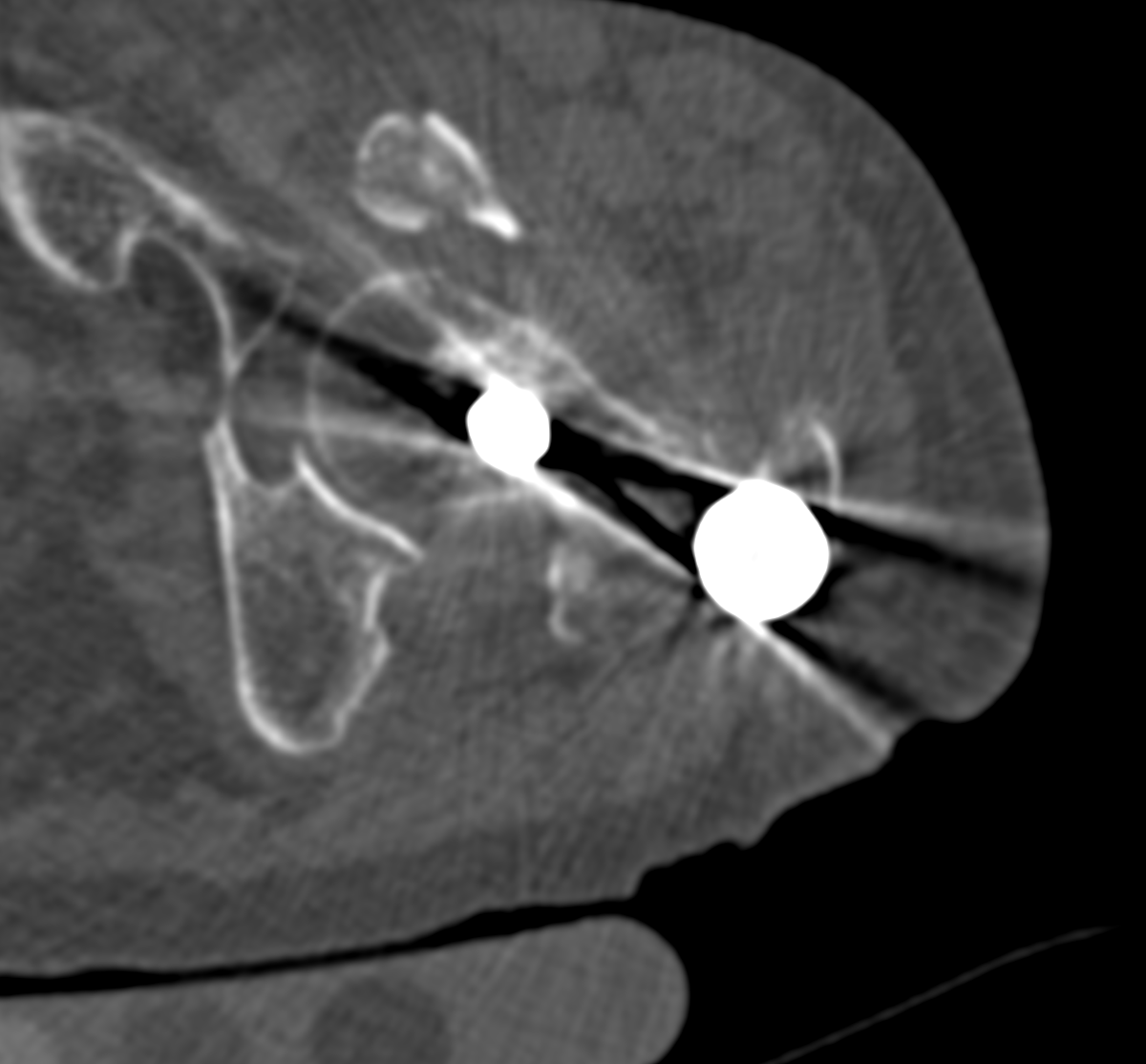

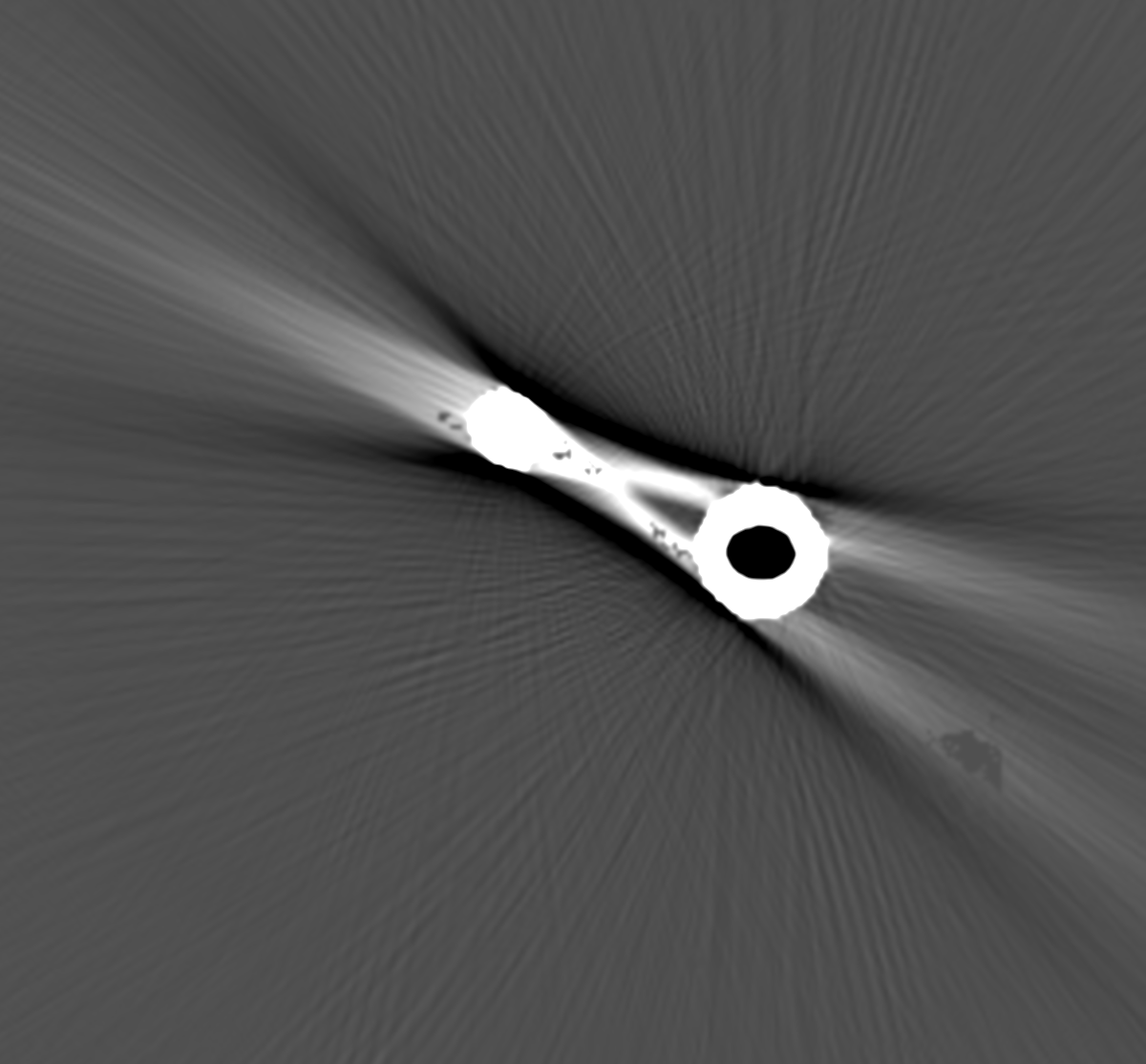

| Here are some typical CT images of someone with a metal hip replacement. Top left shows the errors that result from having metal in the CT scans, and the other images are various forms of correction for these artefacts. Each of these corrections is based on replacing the projected data which has been affected by metal. | It is easier to assess this when scanning a known object: above is a phantom without any metal in, and below scanned again after inserting a pretend hip replacement. | The colour in these images is the difference between the corrected scan, and the real scan with no metal in it, so colours show errors which were not corrected in each case. All of the corrections still have errors over the image a long way from the actual metal, because it is really hard to know how to 'fill in' the gap in the projections where the metal was. |

Metal in CT data is very difficult to image, because the metal is so dense compared to bone or tissue, and hence doesn't let many of the X-rays through. This causes problems when the data is reconstructed (i.e. the cross-sectional image re-created from the measured projections). The assumptions made in the reconstruction algorithm aren't valid for this situation, and result in errors over the whole reconstructed image, often appearing as radial lines emanating from the metal. But CT imaging is used for all sorts of things in medicine: and many people have some sort of metal in their body, either from a hip replacement, or stent, or even from a filling. For instance, this presents a major problem for orthopaedic surgeons who typically would use CT scans to provide the best imaging data for patient treatment.

Most of the correction techniques look at the original projections (the actual data recorded by the CT scanner), work out which bits of these projections were affected by metal, and then try to make up new projection data to replace the corrupted data. There are various techniques for this, among which Refined Metal Artefact Reduction (RMAR), developed at Cambridge, works particularly well. This starts by trying to guess where areas near to bone have had their mean value affected by neighbouring metal, then iterates to reduce the streaks caused by the metal edges. The second stage is highly successful, but the first stage can result in accidentally removing real features in the original image.

|  |  |  |

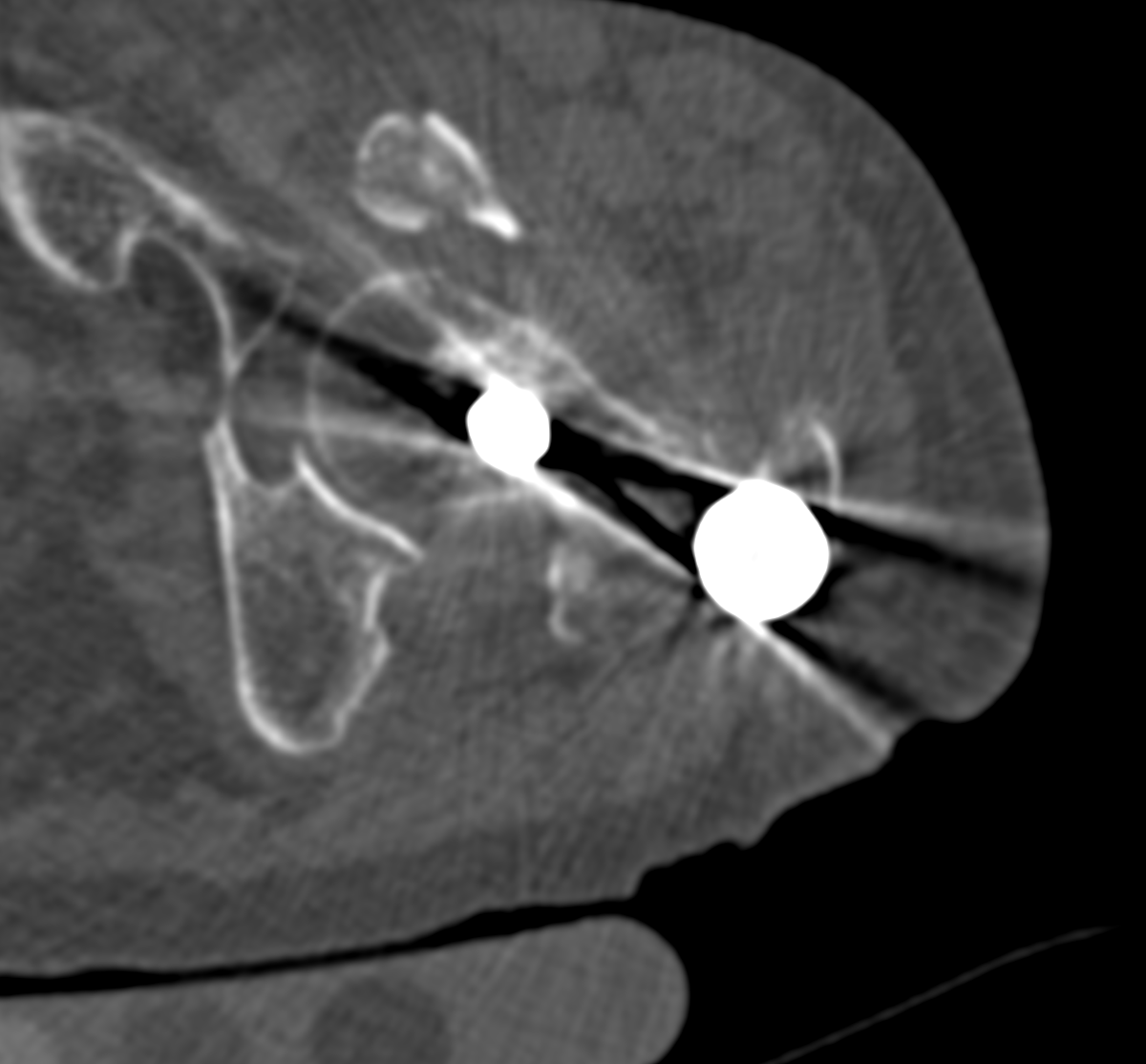

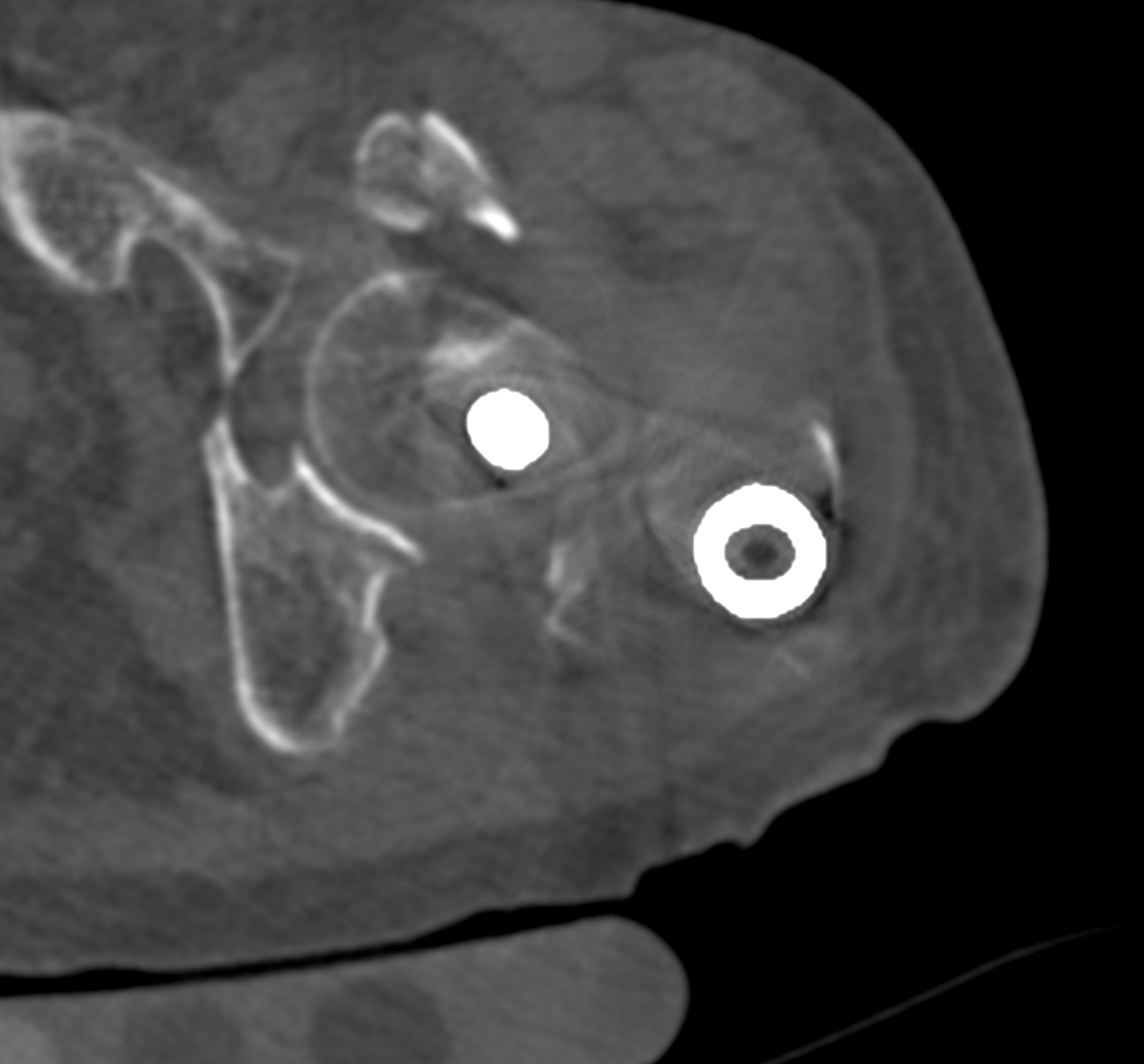

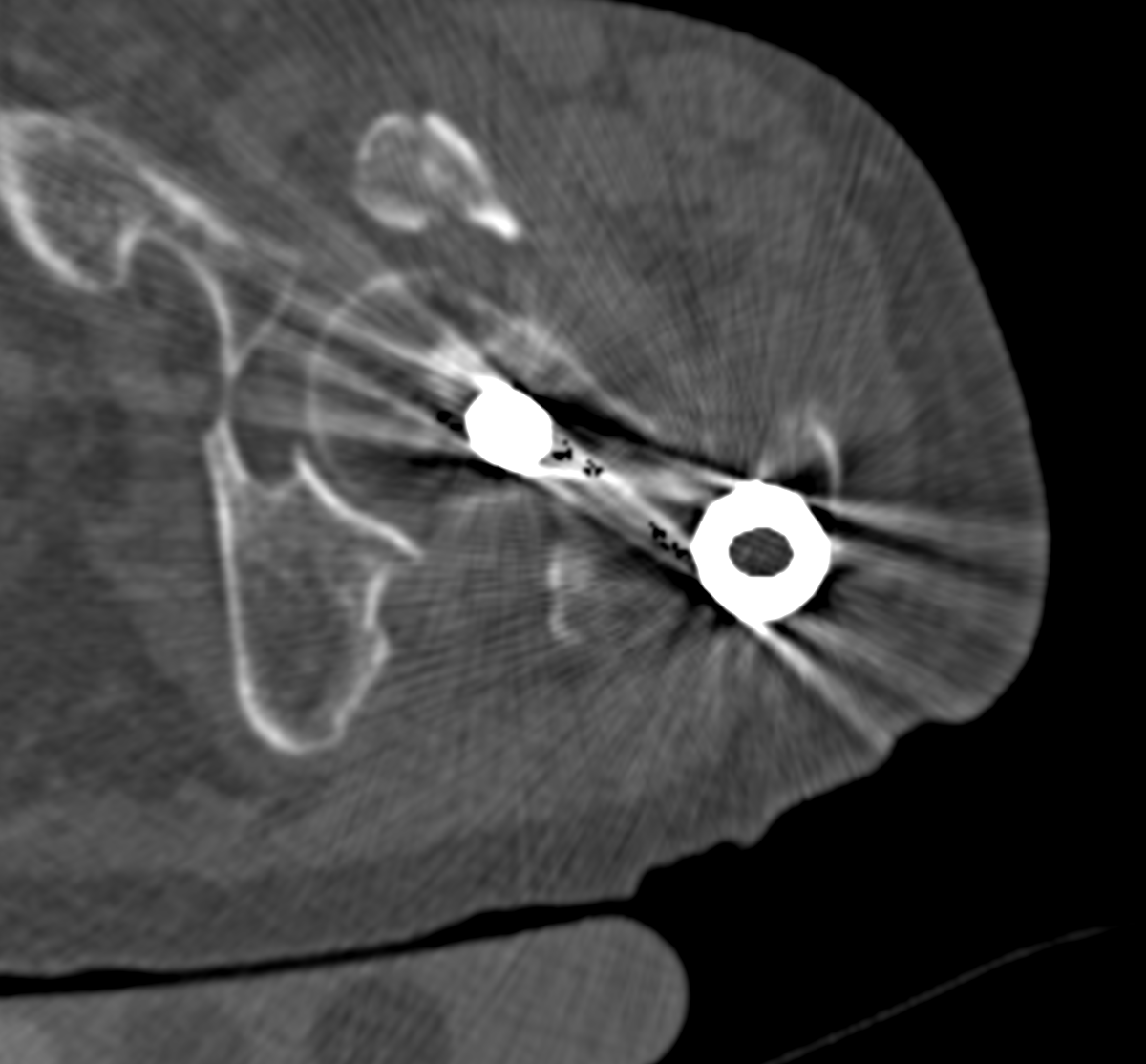

| This is a CT cross-section of a metal implant in the hip | The standard correction using RMAR works, but also removes some bony features near the implants | This is an attempt to directly simulate the incorrect mean values from the geometry of the metal | Overlaying the last two images shows that the simulation is close but not quite right |

The aim of this project is to investigate whether it is possible to use the geometry of the metal implant, and a presumed material for the metal and scanner characteristics, to simulate the reconstruction error from the metal well enough to correct the mean deviations in the original data. This would leave RMAR to correct only the streaking artefacts, which it is already good at. There is some prior work which has established a fast technique for parameterising the artefact which would have been due to the metal. However, fitting this low parameter model to the original data is difficult, and there remain some complex issues related to the limited range of densities usually stored in the typical DICOM data format. Both of these steps are crucial to achieving a useful system for metal artefact removal.

This is an algorithmic development / software project, so experience of writing software is essential, though the development could also be done using Matlab or python or any other appropriate software environment. It would ideally suit someone with experience of the 3G4 medical imaging course.

Click here for other medical imaging projects offered by Graham Treece.