Main > GMT_4YP_18_3

Dr Graham Treece, Department of Engineering

F-GMT11-3: Reducing noise due to metal in CT data

|  |  |

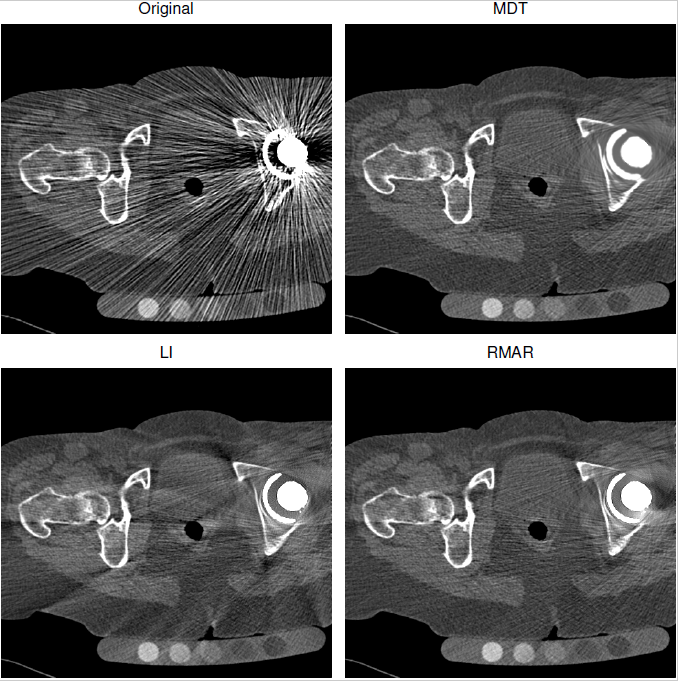

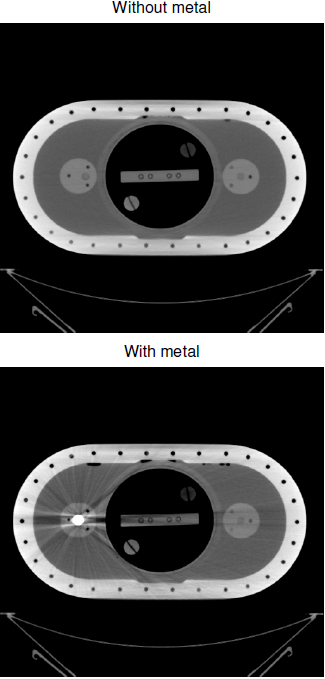

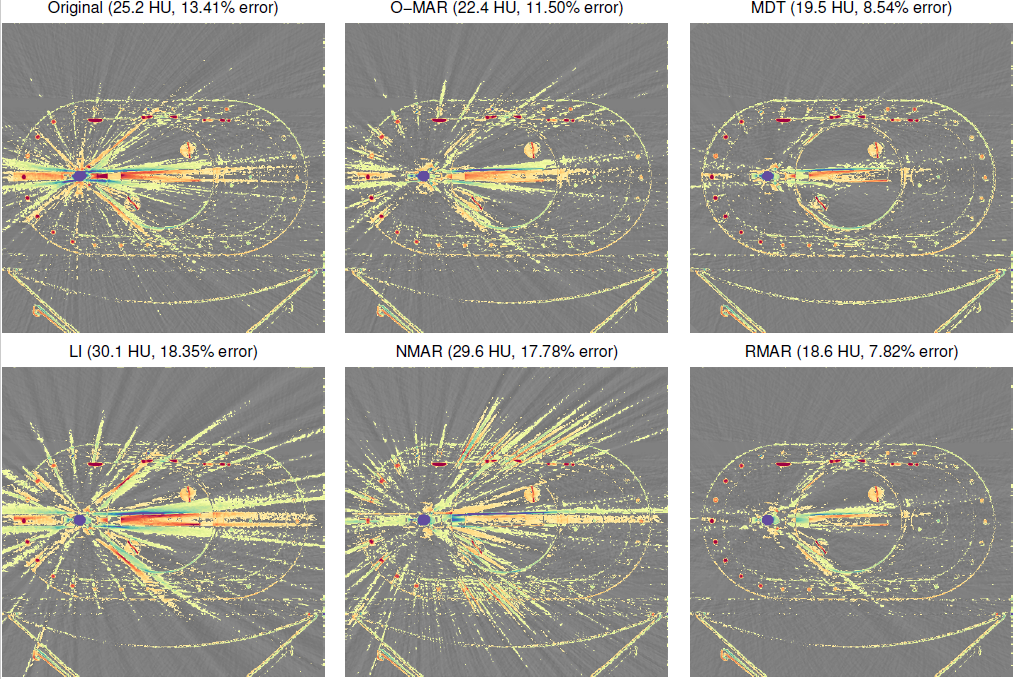

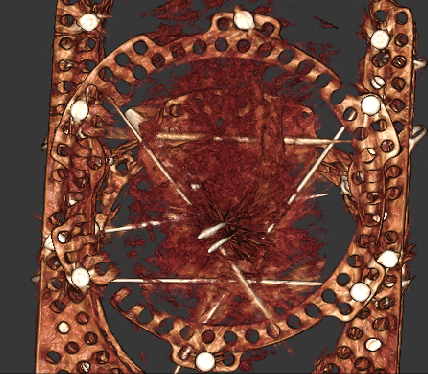

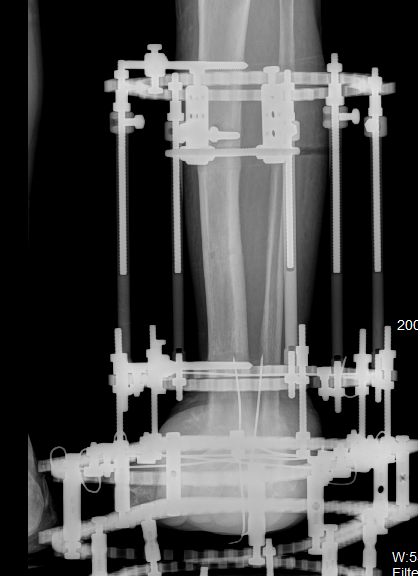

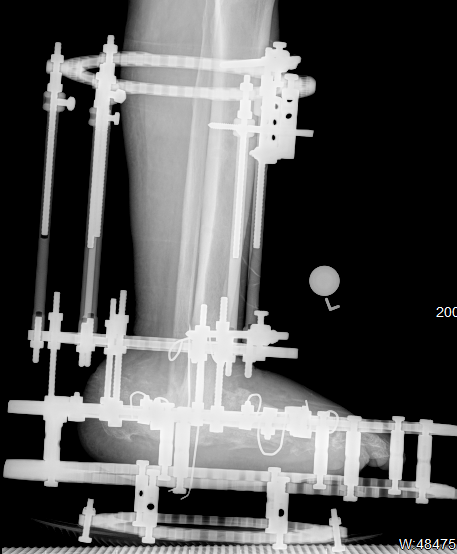

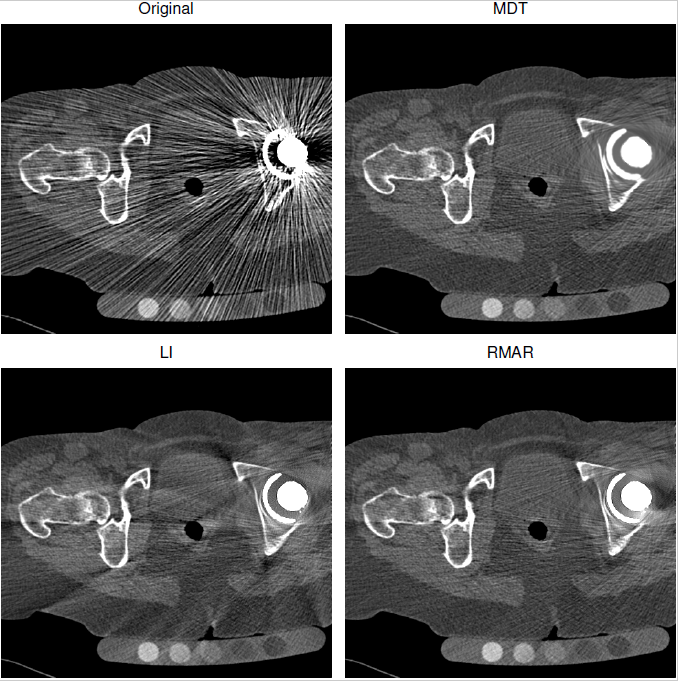

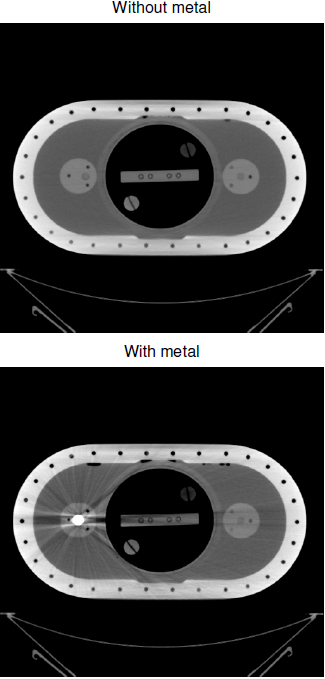

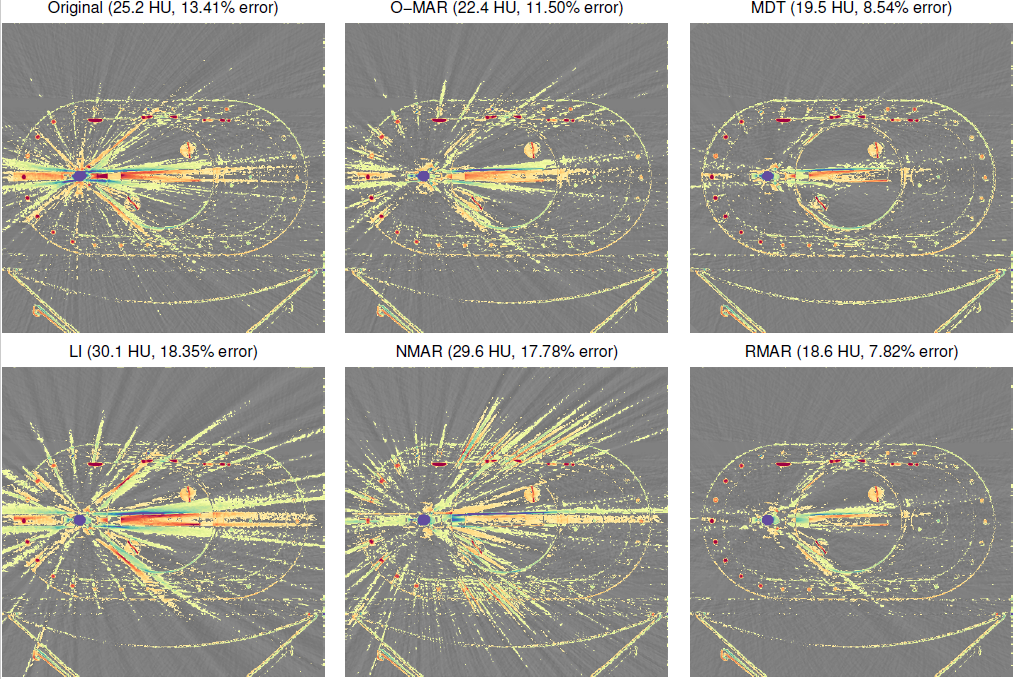

| Here are some typical CT images of someone with a metal hip replacement. Top left shows the errors that result from having metal in the CT scans, and the other images are various forms of correction for these artefacts. Each of these corrections is based on replacing the projected data which has been affected by metal. | It is easier to assess this when scanning a known object: above is a phantom without any metal in, and below scanned again after inserting a pretend hip replacement. | The colour in these images is the difference between the corrected scan, and the real scan with no metal in it, so colours show errors which were not corrected in each case. All of the corrections still have errors over the image a long way from the actual metal, because it is really hard to know how to 'fill in' the gap in the projections where the metal was. |

Metal in CT data is very difficult to image, because the metal is so dense compared to bone or tissue, and hence doesn't let many of the X-rays through. This causes problems when the data is reconstructed (i.e. the cross-sectional image re-created from the measured projections). The assumptions made in the reconstruction algorithm aren't valid for this situation, and the result is errors over the whole reconstructed image, often appearing as radial lines emanating from the metal. But CT imaging is used for all sorts of things in medicine: and many people have some sort of metal in their body, either from a hip replacement, or stent, or even from a filling. For instance, this presents a major problem for orthopaedic surgeons who typically would use CT scans to provide the best imaging data for patient treatment.

Most of the correction techniques look at the original projections (the actual data recorded by the CT scanner), work out which bits of these projections were affected by metal, and then try to make up new projection data to replace the corrupted data. There are various techniques for this, among which Refined Metal Artefact Reduction (RMAR), developed at Cambridge, works particularly well. However, it presumes an X-ray geometry which is reasonably planar. Hence it works well for standard helical CT, but less well for cone beam CT, which is increasingly being used for instance in knee and ankle scanning.

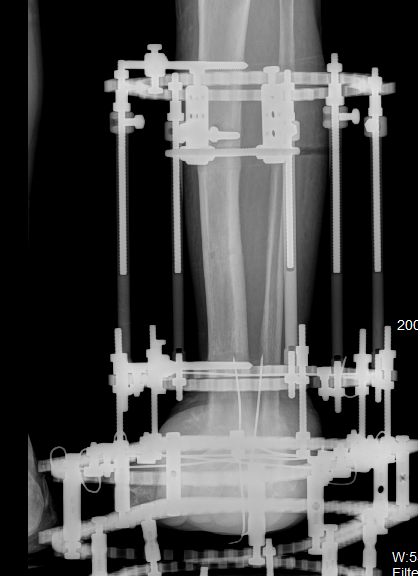

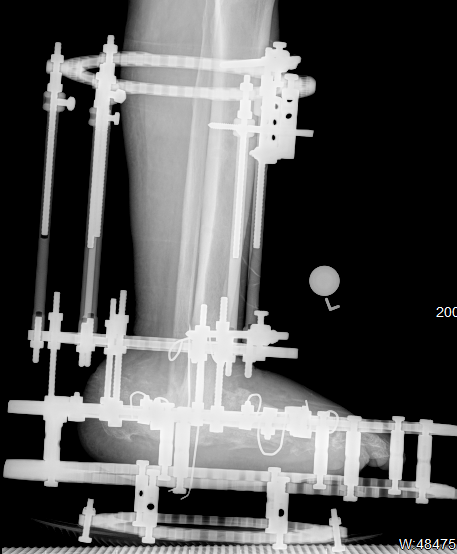

|  |  |  |

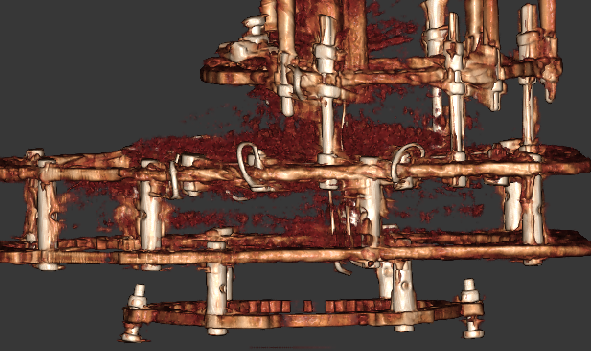

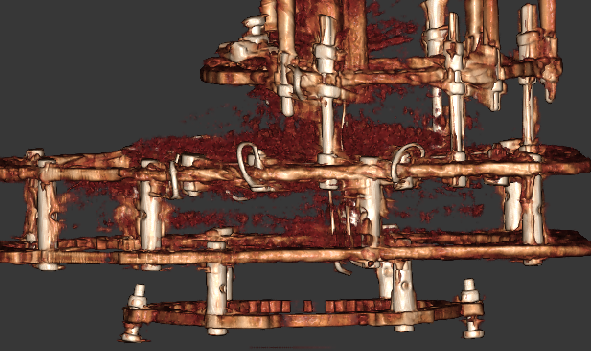

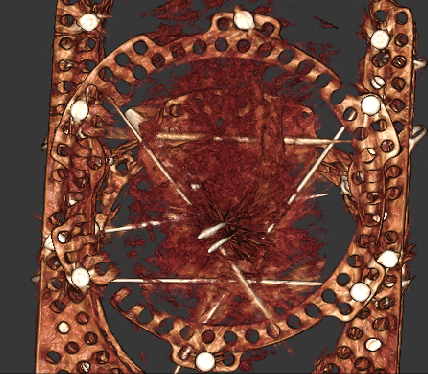

| This is a 3D lateral reconstruction from cone beam CT showing a frame around the ankle. | You can see the frame, but very little of the detail in the ankle. | An X-ray is much cleaner since it doesn't suffer from the same artefacts. | But this only gives 2D projection data and you can't see any of the foot beneath the metalwork. |

The aim of this project is to try to adapt RMAR for the very non-planar geometry in cone beam CT and, in the process, hopefully also improve it for the slightly non-planar geometry in more conventional helical CT. Our orthopaedic surgery partners at the Paley Institute Florida USA have provided us with patient imaging and are also available for clinical relevance guidance. Successful artefact reduction would enable the better assessment of bone healing.

This is an algorithmic development / software project, so experience of writing software is essential, though the development could also be done using Matlab. It would ideally suit someone with experience of both the 3G4 medical imaging and the GG2 CT reconstruction IIA project, or at least one of these.

Click here for other medical imaging projects offered by Graham Treece.